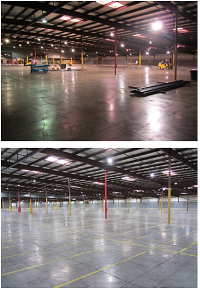

In need of additional space to accommodate their continued growth, Rubbermaid® recently dusted off six mothballed warehouses at their Wheat Road facility in Winfield, Kansas. As you can see from these before-and-after photos, the spaces left much to be desired in terms of existing light – or lack thereof. So Rubbermaid® called on Young Electric, who began by conducting a Lighting & Energy Audit of all six spaces.

In need of additional space to accommodate their continued growth, Rubbermaid® recently dusted off six mothballed warehouses at their Wheat Road facility in Winfield, Kansas. As you can see from these before-and-after photos, the spaces left much to be desired in terms of existing light – or lack thereof. So Rubbermaid® called on Young Electric, who began by conducting a Lighting & Energy Audit of all six spaces.

With the results of the Audit in hand, a comprehensive, six-warehouse plan was developed to increase lighting quality while decreasing energy consumption. A key component was the integration of high efficiency LED fixtures across both large open-space regions as well as custom task lighting areas. Specifically, Young Electric selected RAB Lighting high bay and Barron Trace-Lite® linear high efficiency LED fixtures for the project.

The result? A reduction of almost 65% in energy usage! Specifically, the Lighting Power Density (LPD), a measurement of how efficiently a given lighting level is being provided (think watts per square foot), was reduced by almost two thirds across all six warehouse - that’s a huge savings. Add to that an improved color rendering index and overall lighting quality appearance, and you have one successful project, and one satisfied customer.

So, while you’re looking at the before-and-after photos, imagine driving a forklift, or reading a product label, before – and then after, in a safer and more efficient work environment. The difference is night and day.

We’d like to give special thanks to Mike Adams, Rubbermaid® Facilities Engineering Manager, and also tip our hats to the many other key Rubbermaid® stakeholders that, without them, the project would’ve remained in the shadows.